Food Packaging

CLEAN EFFICIENCY

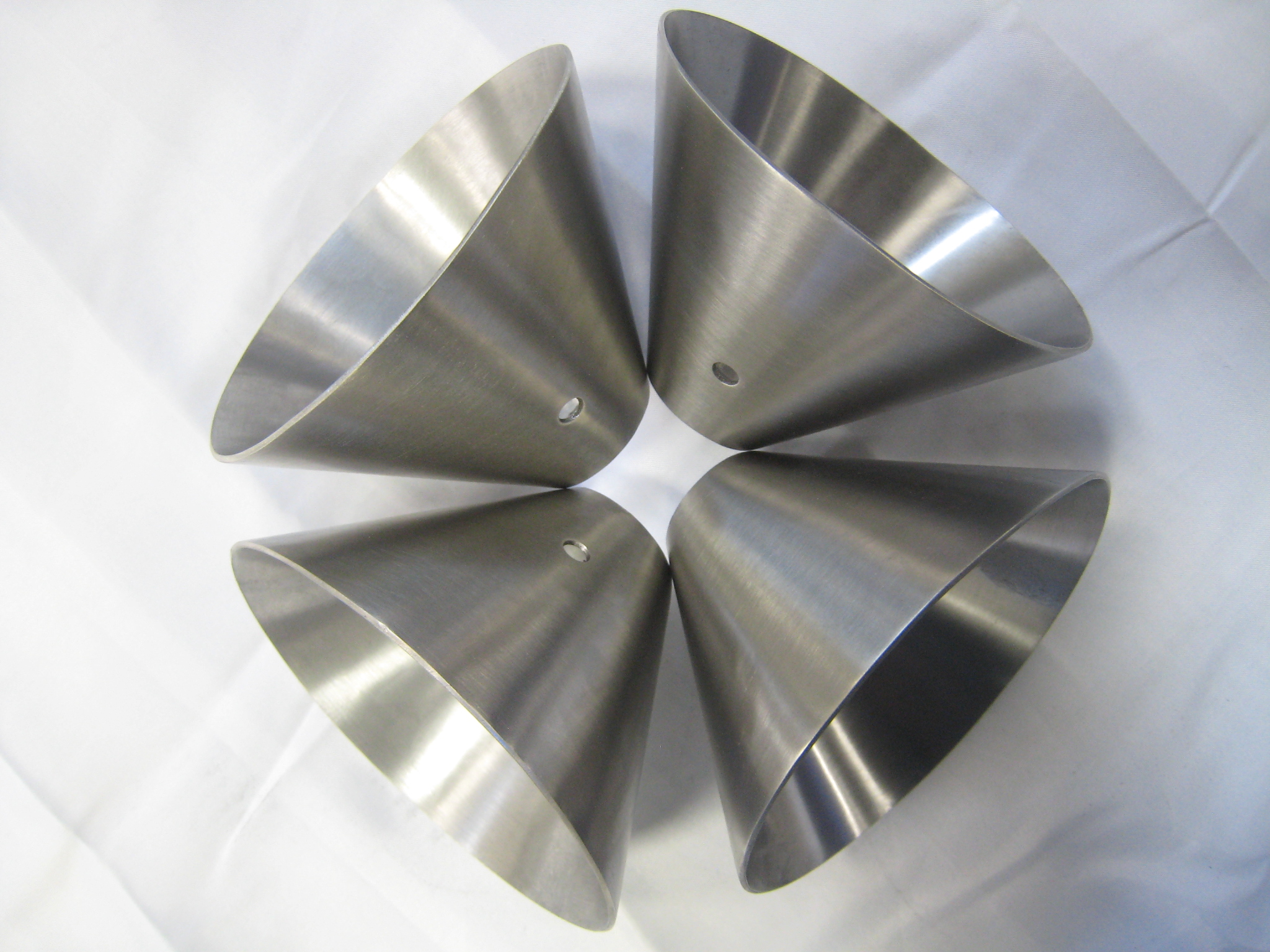

Stainless assemblies built for reliability, hygiene, and uptime.

ACE Metal Crafts Company delivers stainless solutions that keep food packaging lines running cleanly and efficiently. With decades of experience serving global OEMs, we engineer and fabricate components and assemblies that meet both structural and sanitary design requirements — reducing downtime, improving throughput, and supporting continuous operation.

From machine frames and guarding to conveyor assemblies and enclosures, ACE’s stainless expertise ensures every surface is easy to clean and every weld is smooth, consistent, and compliant with food safety standards. Using ERP-driven planning, advanced forming and rolling equipment, and documented inspection, we help our customers meet strict production goals while maintaining the integrity their brands depend on.

In this business, consistency is everything. Our partners expect the same excellence every time, no matter the complexity.

Angela Pitzo, Vice President - Manufacturing

In this business, consistency is everything. Our partners

expect the same excellence every time, no matter the complexity.

Angela Pitzo, Vice President - Manufacturing

Certifications and Expertise

-

3-A / FDA sanitary design compliance

-

Structural & sanitary stainless assemblies

-

Advanced forming, rolling, and laser cutting

-

Uniform bead-blasted and brushed finishes

-

Pre-fit and validated assemblies for fast installation

.png)