ACE Adopts SolidWorks

January 3, 2014

Discover how collaborating with our customer on strategic outsourcing netted a big win for both

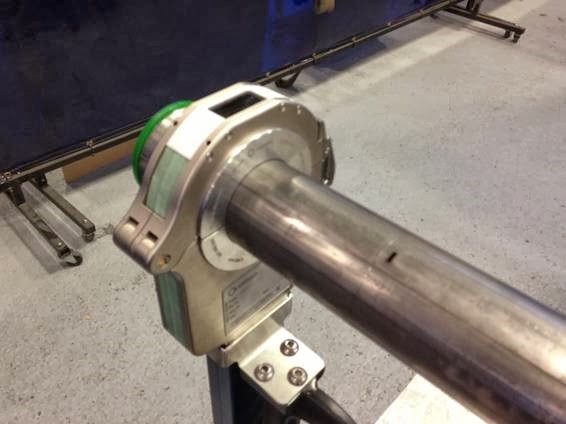

May 6, 2014Some would say, ‘Nothing is perfect.” But at ACE, the perfect weld is routine, thanks to Orbital TIG sanitary welding capabilities. According to VP of Engineering, Kevin Bailey, “The Orbitalum 165 CA is ideal for automatic sanitary tube welding applications. At ACE we focus on sanitary weldments for our OEM partners, and the quality of the weld is as close to perfect as you can get. With this technology, we can offer our customers high standards for applications like stainless steel sanitary tubing weldments, process piping and manifold parts.” In addition to the automated power source, ACE uses the Orbitalum weld head 76S, ideal for food and pharmaceutical applications providing capacity to weld up to 3.0” OD sanitary tubing.

As ACE continues to expand its influence in the sanitary OEM industries, our newly added Orbital Welding System will allow us to better serve our dairy, pharmaceutical and packaging customers.

In a recent interview, Kevin notes, “From a business perspective, there are five key benefits with this technology.

- Gives our customers the option to manufacture their TriClover sanitary fitting and process piping applications with ACE

- Provides consistent, high quality sanitary orbital welds

- Is a cost effective, automated solution for orbital welding

- Meets superior sanitary standards for process piping and other applications

- Opens up new opportunities for our food, dairy, pharmaceutical and packaging customers