The ACE Contract Assembly Advantage

ACE Metal Crafts Company provides build-to-print contract assembly capabilities which deliver your projects on-time, with the attention to detail and workmanship necessary to address your most complex project challenges.

We understand your project may involve several integrated solutions. Our Contract Assembly services are a dynamic collaboration with your team, working as an extension of your manufacturing floor. Our engineers and assembly experts bring significant advantages to your project schedule, and bottom-line.

- We are focused on your key goals, from initial project scope to completion, learning the nuances of your project through open communication and collaboration.

- By applying lean manufacturing concepts, we actively work to reduce project costs and timelines.

- Through our collaborative approach, design issues are immediately addressed by our ACE in-house engineering team, with solutions quickly provided through 3-D renderings so enhancements are made during assembly limiting downtime and keeping your project on schedule.

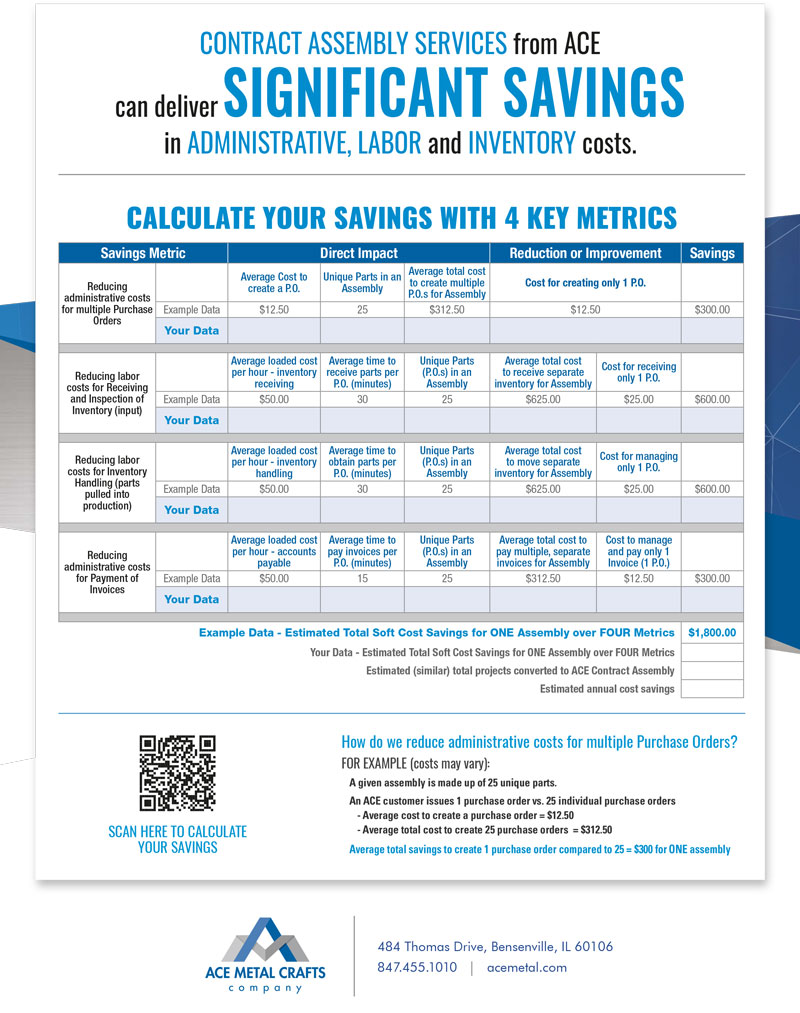

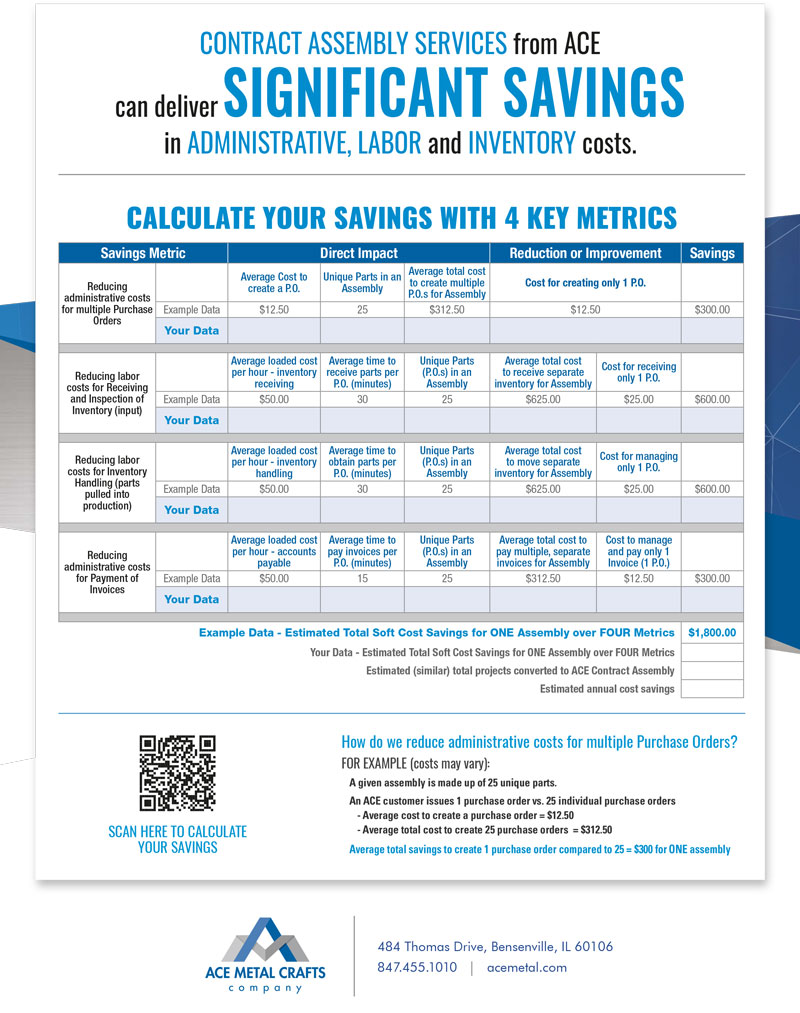

Calculate your Savings in Administrative, Labor and Inventory Costs with ACE Contract Assembly

ELIMINATING, LIMITING & REDUCING

- Receiving parts

- Inspecting parts

- Material handling

- Production delays - time looking for lost parts

- Administration – less purchasing and accounting time

- Inventory

- Lead-time

- Investments in capital equipment

- Recruiting costs

GAINING

- Sanitary belt welding

- Product testing and calibration

- Assembly from 3D models or blueprints

- Production capacity allows you to sell more equipment

- JIT delivery capabilities

- Traceability

- Single part number ordering

- Opportunities for future cost improvements through value engineering

- Dry fitting for quality assurance

- Custom crating and shipping

SUB-ASSEMBLY

With our sub-assembly integrated solutions, we provide streamlined solutions to your project, including:

- Doors/Windows

- Organized part kits

- Modular stations

VALUE ADDED:

- Single piece flow for ordering of multiple part numbers

- Grouping, packaging, and labeling of parts to optimize parts assembly and ensure quality

- Internally focused on proprietary designs

MECHANICAL ASSEMBLIES

We utilize state-of-the-art equipment and mechanical assembly techniques to produce high capacity, quality structures, including:

- Enclosures

- Framework

- Process skids

VALUE ADDED:

- Fit for function

- Modular assembly

- Sub-assembly

MATERIALS:

- Customer supplied material

- Mixed materials (i.e. stainless steel, plastics, aluminum, carbon steel, titanium, epoxy, silicone)

ELECTRO-MECHANICAL ASSEMBLIES

Our electro-mechanical assemblies deliver multi-component solutions which are ready for installation, including:

- Conveyor belts

- Electrical wiring

- Pneumatics

- Mixers

- Weigher scales

- Fillers

- Safety switches & sensors

- Motors

VALUE ADDED:

- Test equipment for functionality based on specs provided

- FAT (factory acceptance test) in-person testing for pre ship inspection (PSI)