Glass Beading

Bead-blasted finishes have aesthetic appeal and can enhance the surface properties of stainless steels. Depending on the sanitary requirements, we can supply various mesh sizes for your specific application.

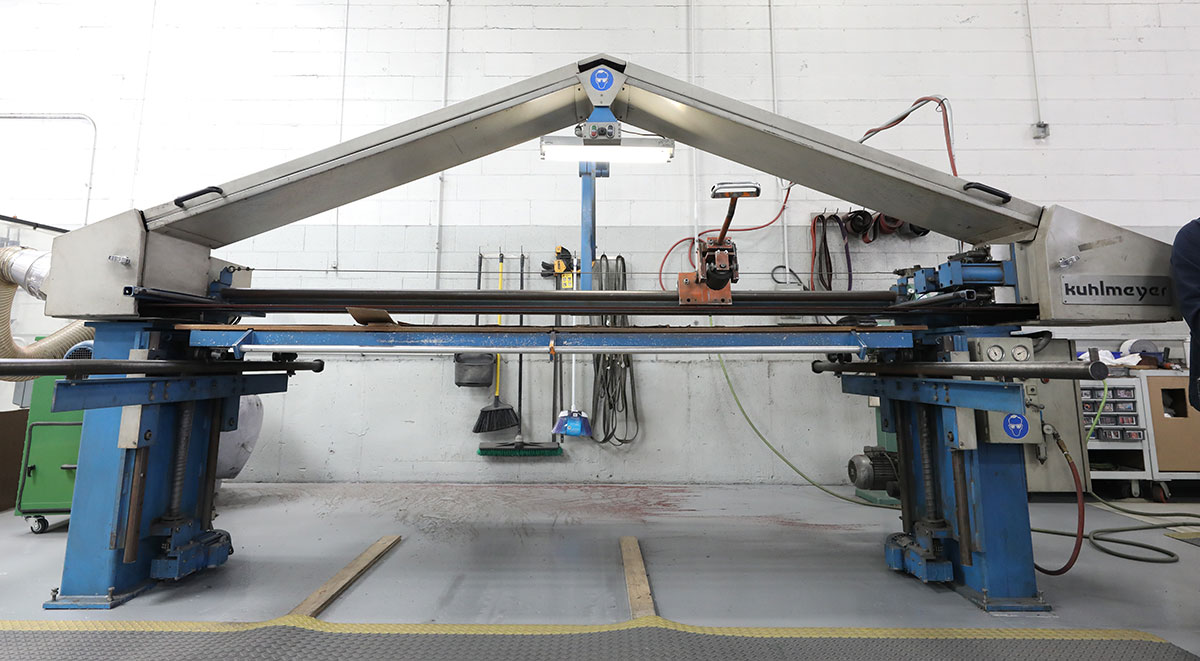

ACE’s 40 x 25 foot glass bead booth, currently one of the largest dedicated stainless booths in the Midwest, has built-in equipment redundancy, eliminating changeover downtime between different mesh requirements.

Operating with two shifts, our glass beading finishing services support our customers with a high degree of scheduling flexibility and rapid delivery timeframes.

EXAMPLE OF STAINLESS STEEL FINISHES

| 2B | Commercial #4 | 3A Dairy* | #4 Sanitary (32 RA or better) | Bead Blast | |

|---|---|---|---|---|---|

| APPLICATIONS | Material handling and processing, direct food contact | Cosmetic #4, for guarding food processing and shrouding | Used in Hygienic clean rooms, 3A Dairy Process and for compliance with 3A Dairy standards | Hygenic clean room pharmaceutical processing and packaging industries where 32 RA or better is required |

Provides a uniform finish for structural, material handling and food handling applications |

| SANITATION | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Bead blasting on some stainless steel alloys is suitable for use in caustic, sanitary wash down procedures |

| NOTES | A 2B finish may be preferable - and more economical - for your application depending upon the specific alloys and compliance requirements of your application | Commerical #4 60 RA or better No. 4 finish is NOT compliant with 3A Dairy Sanitation standards |

Including flat surface finish, all welds must be ground and polished to 3A standard, to meet the requirements of the Dairy and Cheese manufacturing industries | All surfaces and welds are ground and polished to 32 RA or better | Bead blasting does not always produce a 'smooth' finish. The RA, or measure of smoothness, depends entirely upon the stainless base metal used, the blasting media and process. Alloys such as 304 and 316 stainless accommodate this finishing process |

*3A Dairy Sanitation Requirements include stringent attention to fabrication processes that eliminate pits and holes which can harbor bacteria.