ACE METAL CRAFTS COMPANY Acquires Irmko Tool Works

November 13, 2018

Customer Service Is a Mindset, Not a Department

February 15, 2019As we begin 2019, the metal fabrication industry finds itself in a challenging position. From one perspective, metal fabrication is doing very well: capacity utilization is up, and many fabricators are delivering solid performance results. On the other hand, trade tensions continue and supply chains are straining to keep up with demand, while skilled talent remains in short supply — threatening to slow down the current industry momentum. Meanwhile, there are significant digital technologies that are transforming metal fabrication operations. Digital technology advancements hold tremendous potential and is likely to be decisive in determining the fate of industrial manufacturing companies in the months and years to come.[i]

Stock images © Getty Images

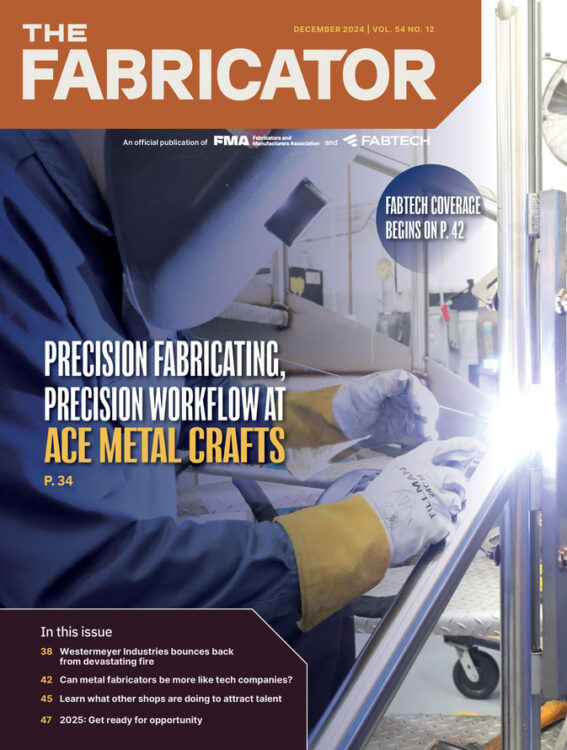

At ACE METAL CRAFTS COMPANY, we continue to embrace process improvements, technology advancements, employee training, as well as company acquisition expansion:

- Our ERP system links our company with a streamlined application that allows all teams to share information seamlessly. Each team, from accounting, to inventory control, to customer service to the value stream leaders throughout the building, can all access data simultaneously and make decisions with real-time details.

- Recently expanded fiber laser technology at ACE has enhanced our ability to offer greater flexibility and hold tight tolerances in cutting various sheet metal thicknesses.

- The investment in water jet cutting equipment, provides one of the most versatile cutting processes available. This technology allows us to cut and hold tight tolerances on plate – without heat affecting the cutting zone.

- Our ongoing employee training provides team members with the knowledge, and skill, to remain up-to-date on emerging technologies, as well as process improvements.

- Our acquisition of IRMKO Tool Works in early November has increased our machining capabilities. This additional ACE location includes a fully equipped shop with over 30 machinists producing precision stainless steel machine components.

As a whole, the metal fabrication industry is in good shape. Although recent tariffs are causing concerns about the future of steel and aluminum prices, metal fabricators are projected to see ongoing strong demand as the market adjusts.

In other words, even with inflation, the ongoing skills gap, and the growing trade war surrounding the recently imposed steel and aluminum tariffs, the metal fabrication industry is poised to increase steadily in 2019. At ACE METAL CRAFTS COMPANY, we look forward to an exciting new year bringing our passion and experience to your next stainless steel fabrication project.