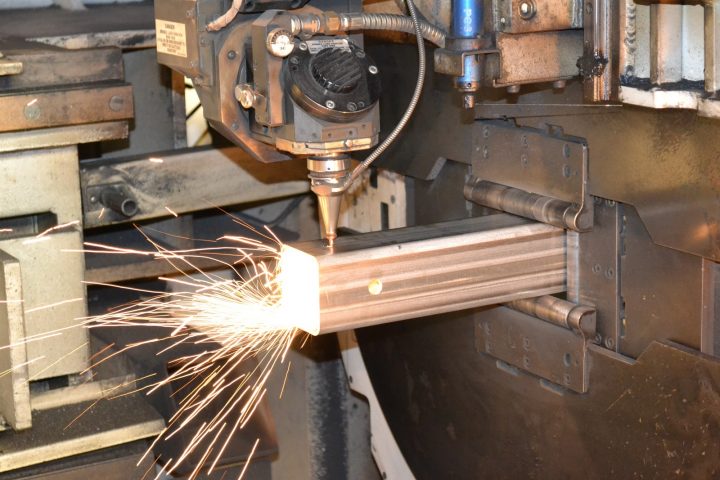

Producing sanitary frames with lightning speed and accuracy is now possible with the tube laser

April 2, 2013“They’re doing stuff with their tube laser that eliminates the need for a tape measure on the shop floor—making it fool-proof!” – ACE Customer

At ACE, we focus on Value Engineering. This means we take your product and engineer a better outcome, like improving the end quality. Here’s a “for instance.”

With our tube laser, we go in and make slots and tabs in the tube. We also etch the surface for component parts. This ensures that the welder is always in the right location. We actually give the welder a 3D assembly print with visual work instructions to match A to A and B to B. As one of our customers likes to say, “You can’t screw it up!” This plays an important role in eliminating mistakes around interpreting a print. It dramatically reduces reworks—that means lower labor costs and consistent quality. Repeatability is assured.

We even thread parts with the integrated CNC tapping heads, eliminating secondary operations and associated materials handling. Whether it’s small to medium, thick or thin-walled, round, square, rectangular, triangular, I-Beam, H-Beam, C Channel, stainless, mid-aluminum, oblong holes, slots or tabs. If your engineers can dream it, ACE can process it with our advanced Mazak FABRIGEAR Tube and Pipe Laser.