Nitrogen Gas – For Laser Cutting AND Coffee…

March 23, 2017

We Can Bend the Thick Stuff…

May 18, 2017Marc Rumer works on the six-cylinder engine final assembly line at Toyota West Virginia. Rumer has been a team member at the Buffalo plant since 2000.

GUEST COLUMNIST – Jim Lentz, chief executive officer of Toyota Motor North America.

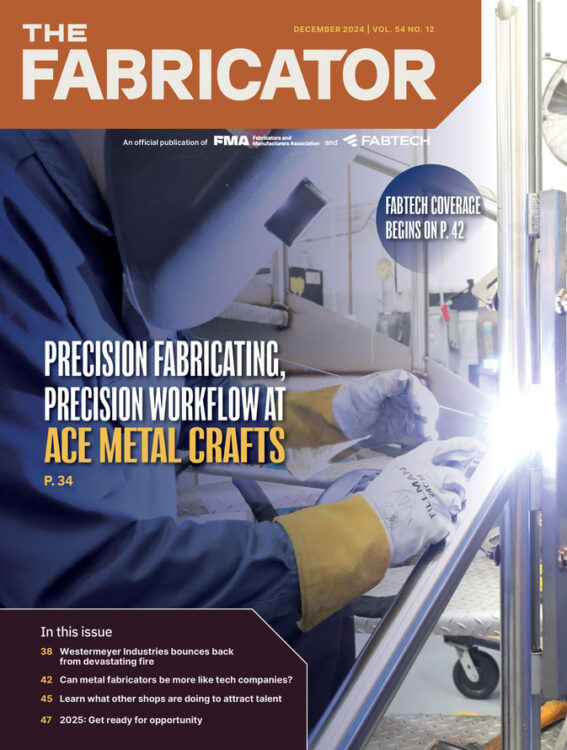

Jean Pitzo faced her biggest challenge as CEO of Ace Metal Crafts: the family owned manufacturer was told by its largest customer that they wanted their product delivered twice as fast.

In Pitzo’s words, the Bensenville, Illinois, stainless-steel fabrication and machining company had become “chaotic and in many instances not meeting customer demand.” She knew if she did not overhaul operations, there would be dire consequences. So she turned to an unlikely partner – Toyota.

For 25 years, we’ve dedicated a staff of Toyota advisors whose sole job is to travel the United States, roll up their sleeves and collaborate side by side with businesses and nonprofits.

Toyota advisors go and see exactly how these partners operate on a consistent basis. And together, we identify solutions that neither party could have come up with on their own; not just by talking, making a presentation or cutting a check, but by doing what we do best – developing people.

We help engage the men and women who understand the company’s needs to serve as the problem solvers and innovators of their organizations. And we’re seeing very positive results. Companies like ACE Metal Crafts are overcoming the challenge of shortening lead times from order to delivery.

As Pitzo said, “we’ve gained more orders, more customers. Not only did we not let anybody go, we added 20 more people… the whole purpose of our company is not about bending metal, it’s really about unleashing potential in people.”

In my opinion for a company of 116 employees, that’s a pretty big deal.

People ask me how and why we do this. It’s simple. After many decades of refining and improving our manufacturing know-how — the Toyota Production System (or TPS for short) — we decided to share our “secret sauce ” (or Toyota’s DNA) with small to mid-sized entities because we believe American companies can manufacture successfully in the United States while competing on a global scale. Sharing our know-how helps our partners stay competitive and helps preserve or create jobs, and that benefits us all.

In addition to keeping or creating jobs, TPS has also helped other organizations such as food banks, hospitals and government operations go beyond their immediate reach to better serve customers or people in need.

And after partnering with over 200 companies, we’ve learned significantly from them as well. We believe in building where we sell, but in order to do so competitively companies (Toyota included) must engage those closest to the work (or process) to make lots of small improvements that lead to great results; when this happens, we’ve learned we can have a significant impact on competitiveness.

If sharing our know-how can help U.S. companies preserve or create high quality jobs, or food pantries and soup kitchens serve more people in need, then we know we have made a meaningful contribution.

I’m proud of Toyota’s contributions and growing footprint in the U.S. We have 10 manufacturing facilities, 1,500 dealerships, 136,000 direct and indirect employees, and plan to invest $10 billion over the next five years here in the U.S., alone. But, nothing defines Toyota more than this sharing of ideas which is a huge win for us all.

Jim Lentz is chief executive officer of Toyota Motor North America.