Toyota advisors fuel small businesses across the USA

May 16, 2017

ACE METAL named to The FABRICATOR magazine’s FAB 40

June 28, 2017

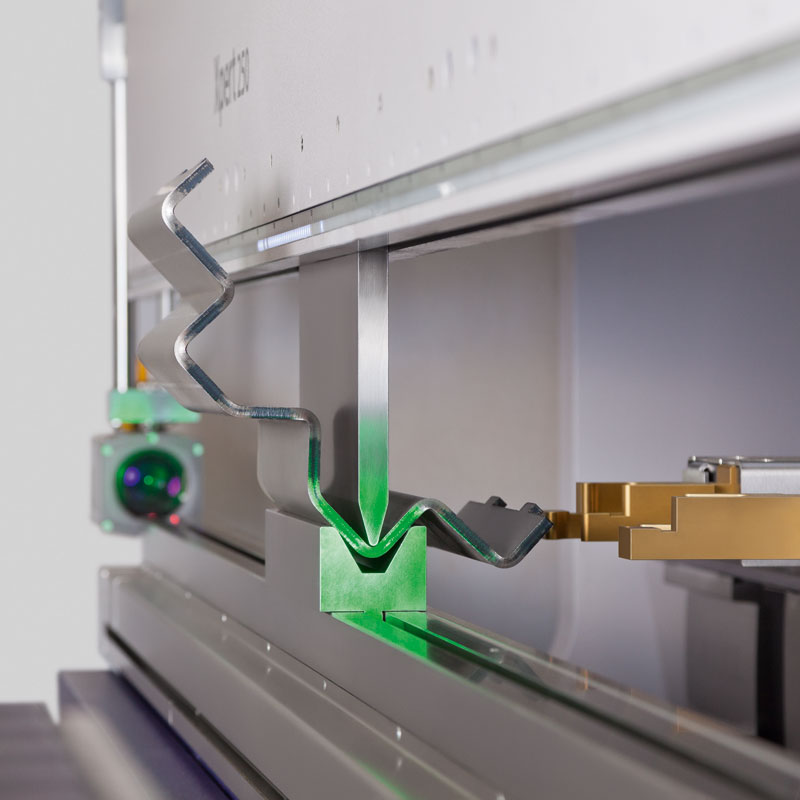

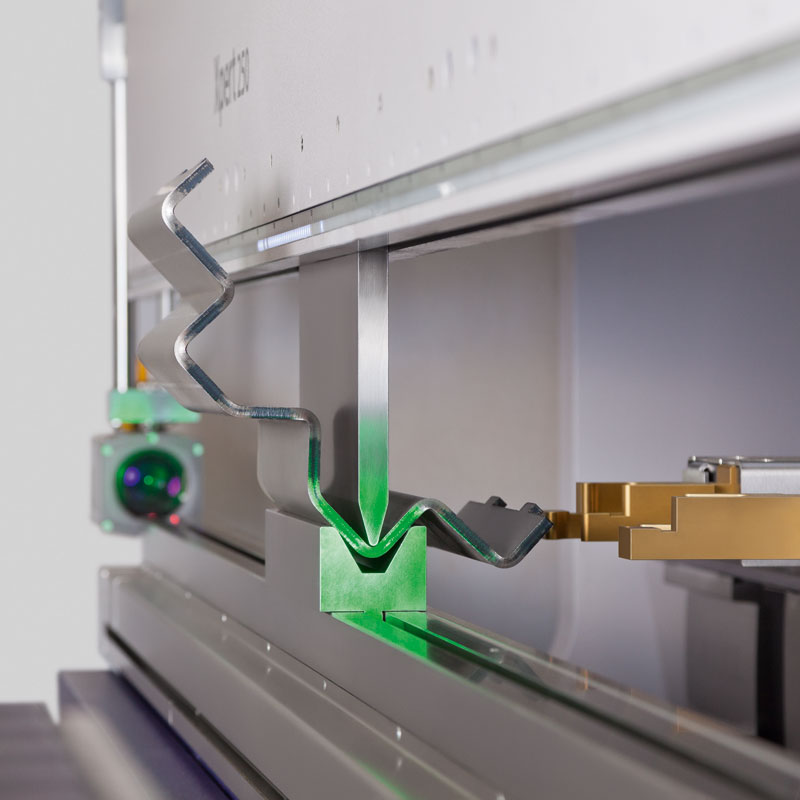

ACE adds to it’s strengths as a single-source supplier with our new Bystronic Xpert 320 Press Brake.

Our bending strength has increased - by 60% - when it comes to the tonnage power over our existing 220 brake.

And, more importantly, our newest addition increases our ability to accommodate more diverse projects, complete them to specification in shorter time frames and deliver a single-source solution for our customers.

The team at ACE METAL CRAFTS COMPANY continuously focuses on how best to meet the changing needs of customers - whether by providing improved processes, scaling to meet increased demand - or investing in new technology.

Earlier this Spring, the ACE team made room for, uncrated and installed the Bystronic Xpert 320 - as seen in the time lapse video.

Measuring 16.3 feet long x 6.6 feet wide x 10.5 feet high our new Xpert 320 can bend the thick stuff using 352 US tons in bend lengths up to 13.4 feet… the tonnage of 352 represents an increase of 60% in power over our existing 220 brake.

This German-built press brake is the most technologically advanced of its type in the world, delivering precision, accuracy, repeatability and speed with features that include:

- Independent 5 axis back gauge

- Intelligent safety system with tool detection

- Thickness monitoring

- Dynamic bending pressure regulation

- Energy saver system

- Optical bend guiding system

- Laser angle measuring system with automatic correction

The advanced control system monitors side frame deflection and system temperatures every eight milliseconds and automatically compensates during each bend. The comprehensive database of bend allowances, tooling shapes and material types, allows for quick and precise bends with extremely high repetition accuracy.

The newest addition to our press brake line operates with 3-point or air bending techniques, to ensure maximum angle accuracy and high precision forming, maintaining maximum repeatability, accuracy and flexibility.

- 352 tons of force

- 18" RAM stroke

- 29" of open height (ideal for fabrication of deep boxes or lengthy flanges)

- The only machine that doesn’t produce angle errors, offering the highest repetition accuracy on the market

- Fully-automatic dynamic crowning function moves and adapts pressure in the bed according to material (ensures accuracy of bends, regardless of the grain direction, length or thickness)

- Dynamic sheet supports to allow single operator operation on large sheet and plate parts

In addition to the combined strength AND precision, our newest investment is speedy, too...

- Fully comprehensive CAD/CAM: there are only six mouse clicks between 3D data file and 3D part

- Hydraulic tool clamping for fast setup and heightened flexibility

- Bybend graphic CAM software which allows for direct importing of DXF, DWG, IGES files