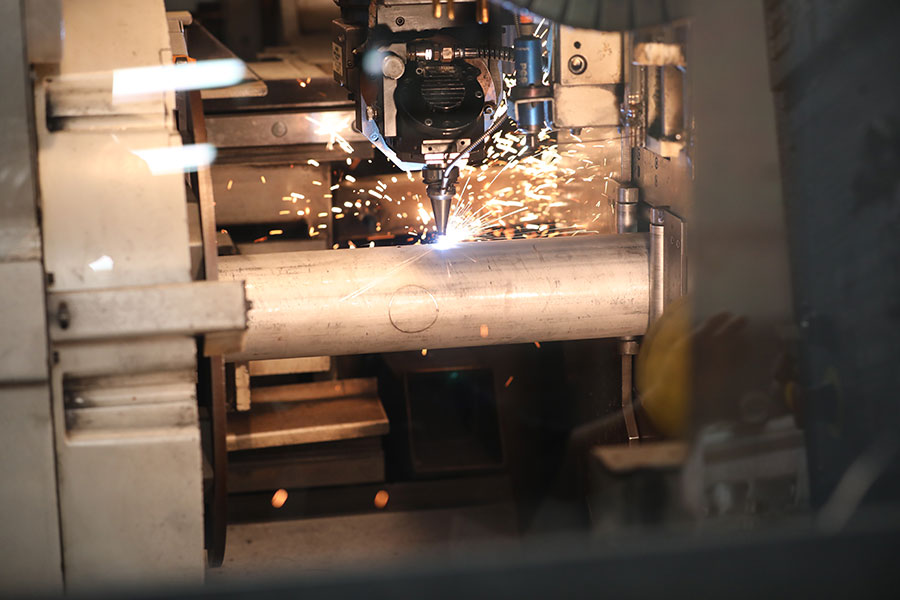

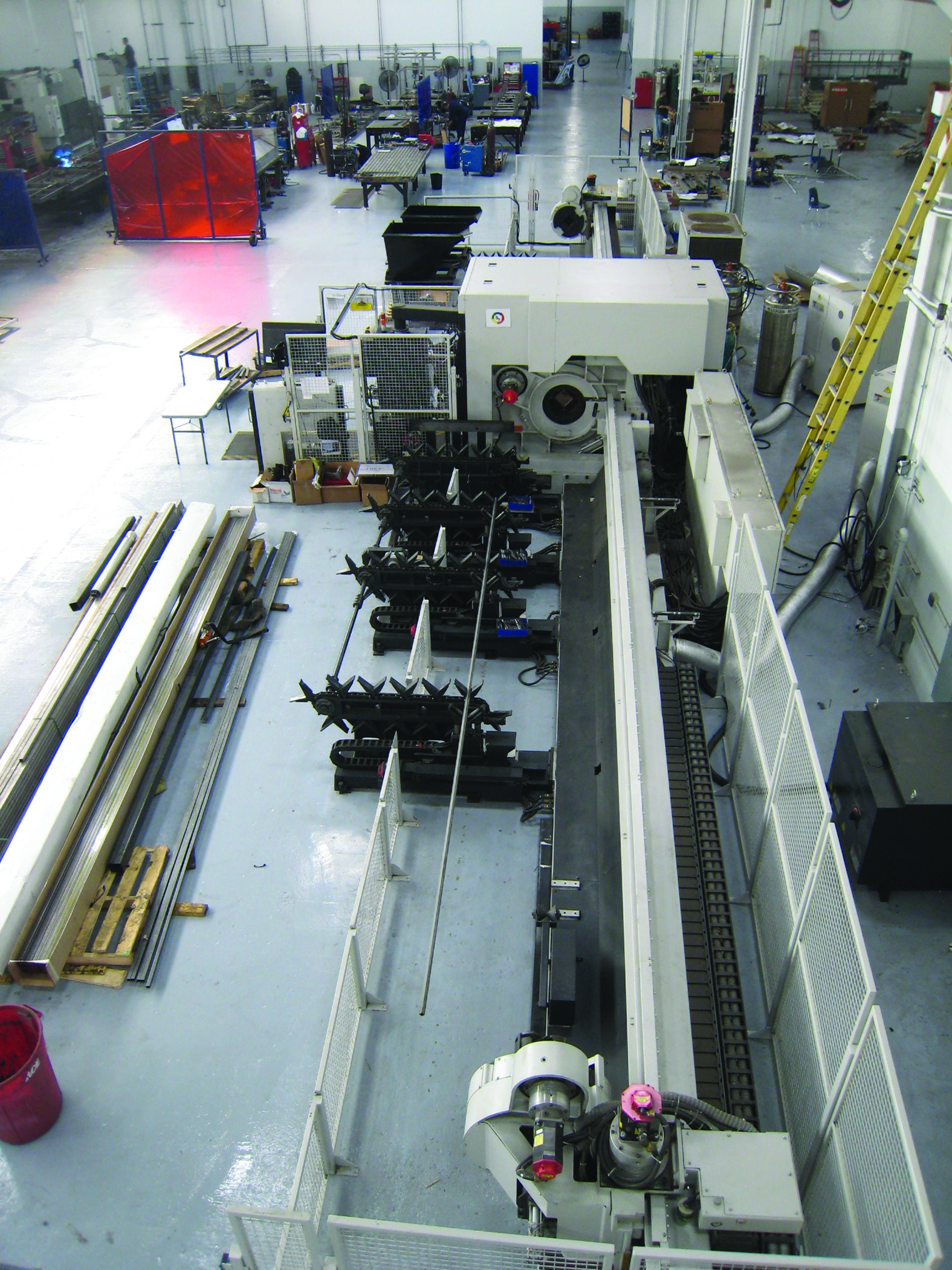

CAPACITY:

- Material types include

- Tube, pipe, square, round, c-channel and angle

- Mild steel: 1/2” wall

- Stainless steel: 3/8” wall

- Aluminum: 1/8” wall

- 6 axis head for bevel and weld prep

- 6 station automatic tapping up to 1/2-13 or M12

- Automatic load and unload

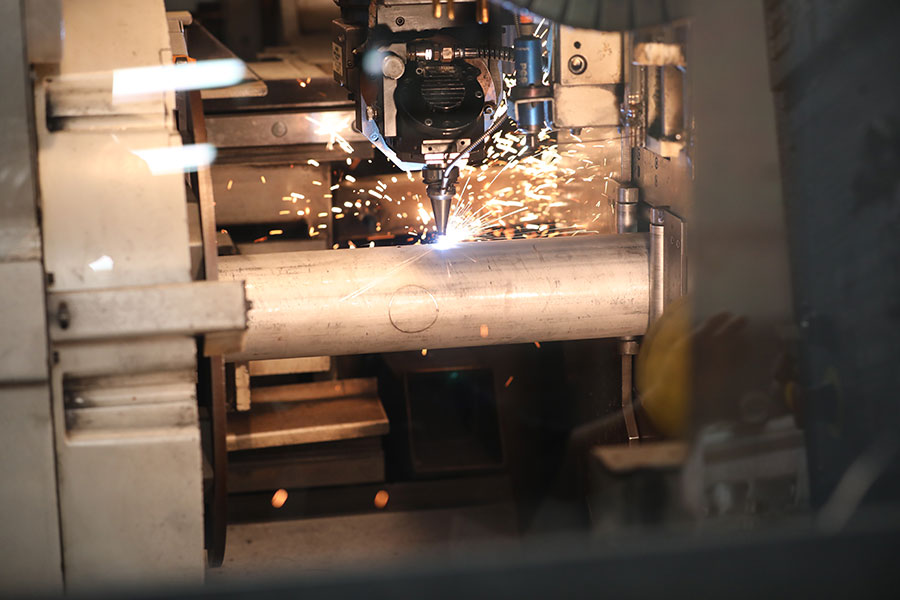

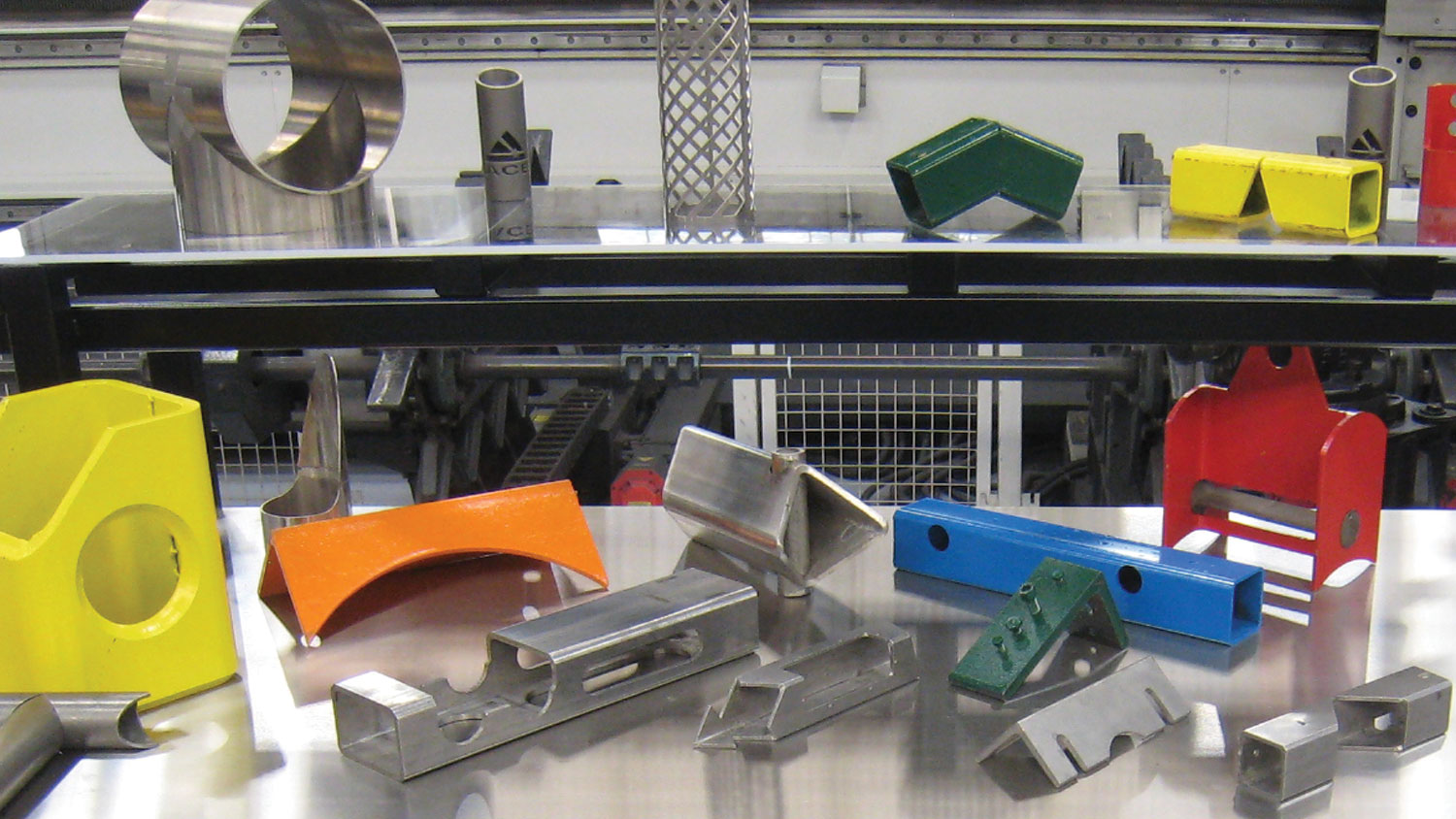

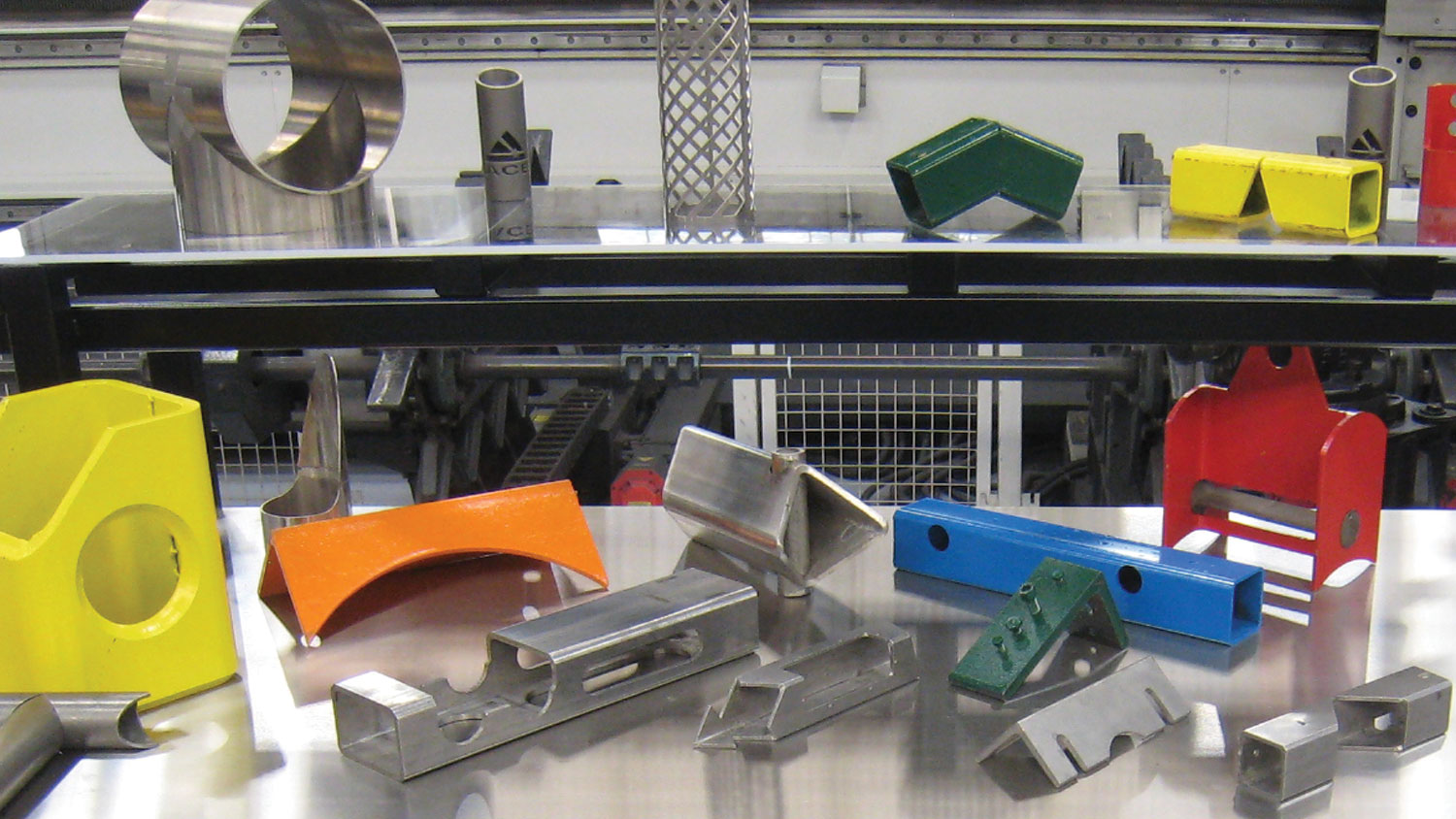

Flat Sheet Laser Cutting

ACE laser cutting technology has the ability to cut up to ½” stainless while holding tolerances of +/-.005”. Directly linked to production CAD systems, we manage a seamless flow of products from design to production.

In-house nitrogen generation provides a 99.99% purity level to ensure our lasers produce weldable, clean-cuts for improved weld quality.

- Mitsubishi eX-F 6000 Watt Fiber-Optic Laser with a 60" x 120" bed size and automated sheet loading tower

CAPACITY:

- Mild steel to 5/8” thick

- Aluminum to 3/16” thick

- Stainless to 1/2” thick with nitrogen clean cut

Waterjet Cutting

With an investment in the Flow Mach 3 Series 6’ x 12’ Waterjet Cutting Machine and integrated Dynamic Cutting Head, ACE offers unbeatable accuracy, speed, and flexibility.

The integrated Dynamic Cutting Head adjusts the angle of the cut virtually eliminating the “curf” from the edge of the part, producing tight part tolerances, even at high speeds.

The patented Dynamic waterjet technology with Active Tolerance Control is capable of cutting almost any type of material or thickness, with no Heat Affected Zone (HAZ), reducing warping and material shrinkage.

Use the ultimate waterjet advancement to cut faster, better and less expensive.

- 1 – Flow Mach – 3 – Dynamic Cutting Head 60,000 PSI,

Oversized 72” x 144” bed adds production flexibility

CAPACITY:

- Up to 8” thick material