As important as the use of stainless steel is in pharmaceutical production, packaging requirements in today’s highly competitive pharmaceutical industry require an equal amount of attention.

With combined goals of meeting FDA and industry requirements while incorporating production processes that reduce costs and maximize efficiencies, pharmaceutical packaging lines rely upon the beneficial properties of stainless steel components that offer ease of maintenance for cleaning, sanitizing and resistance to corrosion.

Whether your application requires the use of highly polished stainless steel in product contact processes or you’re looking to provide enhanced aesthetics for non-sanitary processes after capping, the ACE team is committed to providing a wide range of Value Engineering services.

Our commitment to Value Engineering means our staff of engineers will review your drawings and make recommendations to the fabrication plan, ensuring the manufacturability of your designs at a competitive cost.

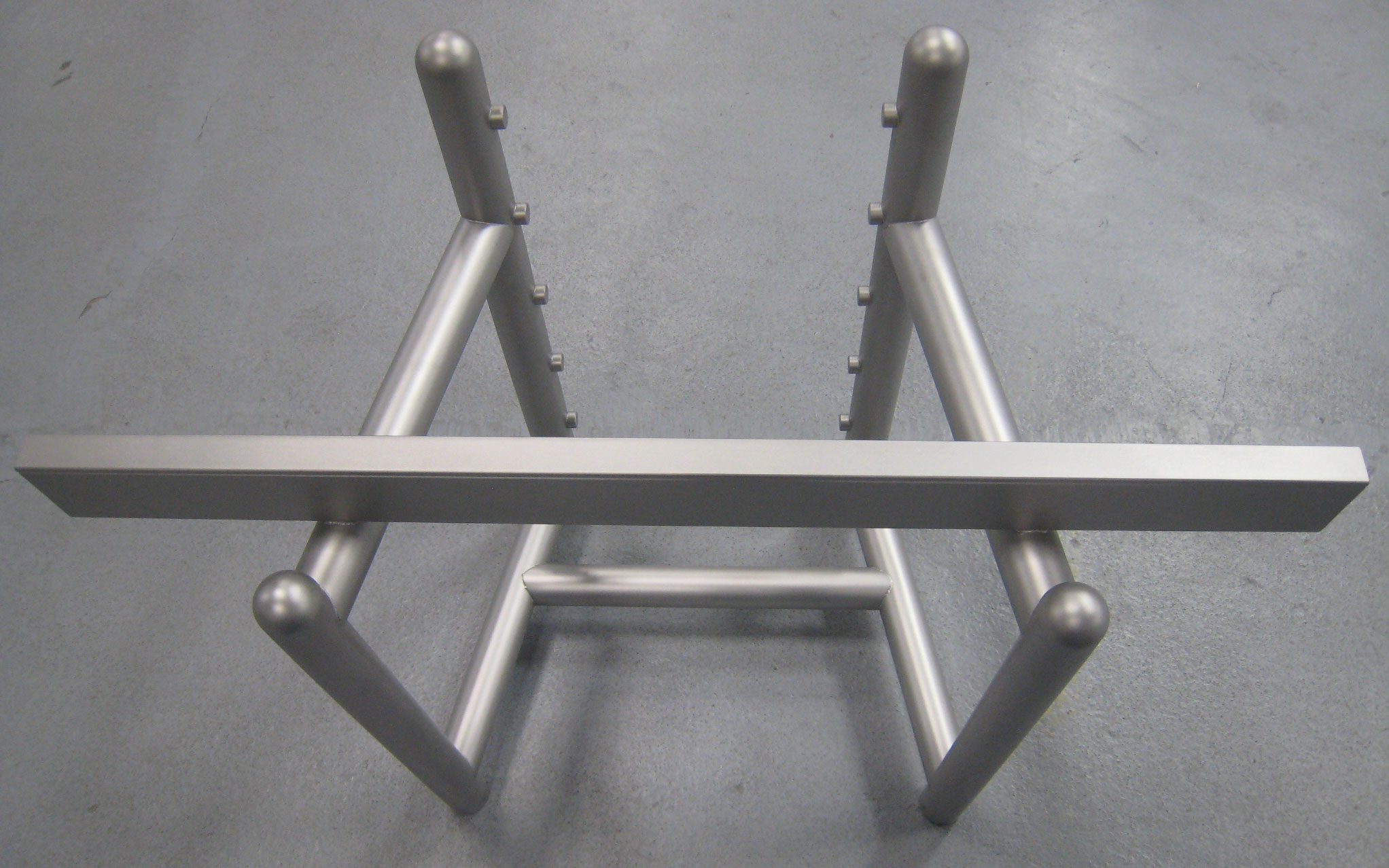

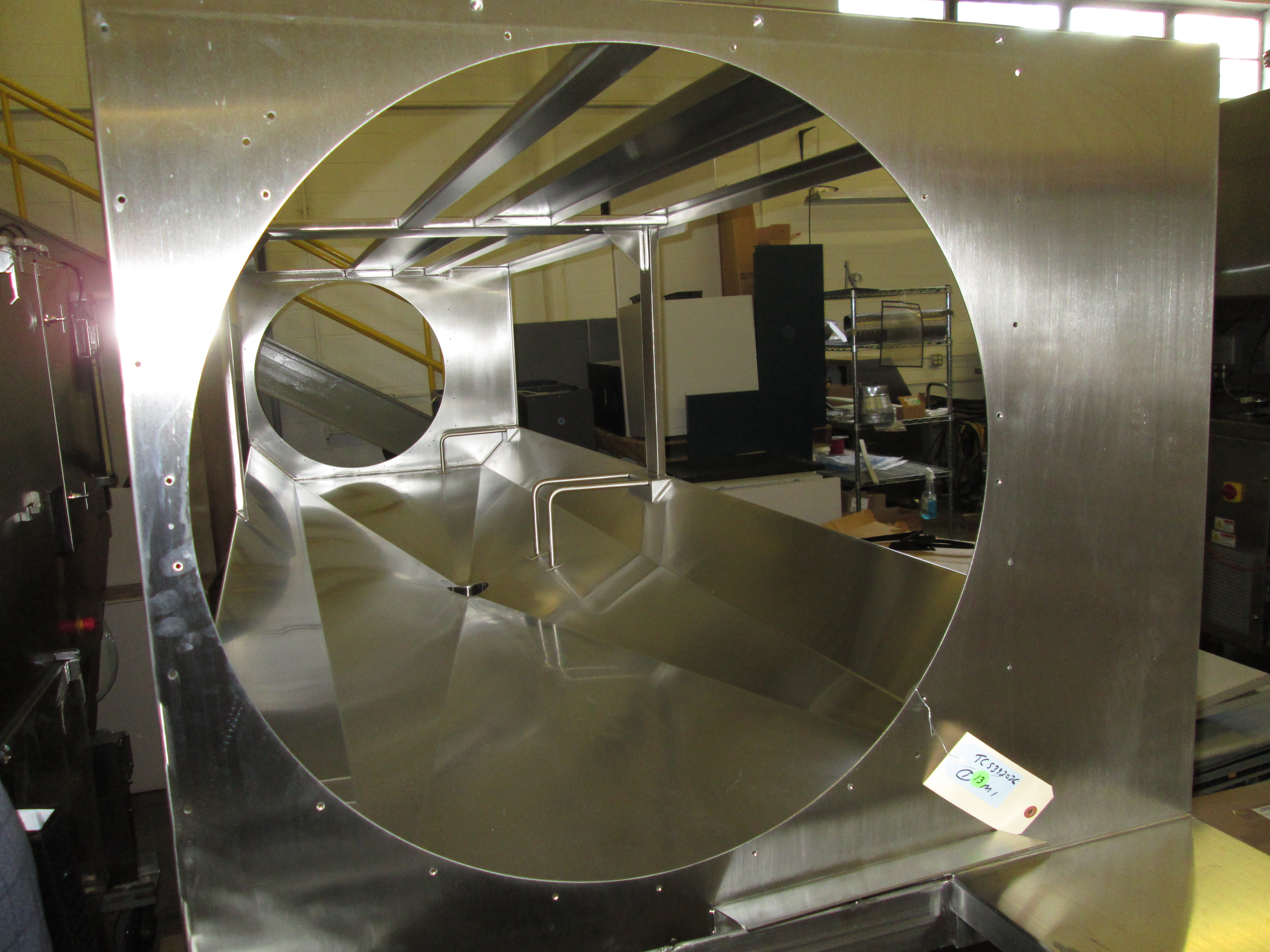

Some of our examples for packaging equipment components used in the pharmaceutical industry include:

EXAMPLE OF STAINLESS STEEL FINISHES

| 2B | Commercial #4 | #4 Sanitary (32 RA or better) | Bead Blast | |

|---|---|---|---|---|

| APPLICATIONS | Material handling and processing, direct food contact | Cosmetic #4, for guarding food processing and shrouding | Hygenic clean room pharmaceutical processing and packaging industries where 32 RA or better is required |

Provides a uniform finish for structural, material handling and food handling applications |

| SANITATION | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Bead blasting on some stainless steel alloys is suitable for use in caustic, sanitary wash down procedures |

| NOTES | A 2B finish may be preferable - and more economical - for your application depending upon the specific alloys and compliance requirements of your application | Commerical #4 60 RA or better No. 4 finish is NOT compliant with 3A Dairy Sanitation standards |

All surfaces and welds are ground and polished to 32 RA or better | Bead blasting does not always produce a 'smooth' finish. The RA, or measure of smoothness, depends entirely upon the stainless base metal used, the blasting media and process. Alloys such as 304 and 316 stainless accommodate this finishing process |