Now, more than ever, the safety of our food supply is of paramount importance. At ACE, our manufacturing and fabrication of stainless steel components must take into account the ultimate end-user, the food consumer, as the need for healthy, reliable and plentiful food sources continues to expand.

Our team of engineers, welders and polishers are knowledgable experts at efficiently producing stainless steel components with a wide variety of hygienic finish requirements, including the exacting 3A Sanitary Standards required for the dairy industry.

As an OEM of food processing equipment, your engineers understand and apply the FDA’s many regulations regarding the the materials used in all machine surfaces that contact food - as well as the lesser standards for non-contact surfaces.

There are many types of stainless steel, offering a variety of tradeoffs in corrosion resistance, magnetism and machinability.

As a part of our Value Engineering services, our staff of engineers will review your drawings and make recommendations to the fabrication plan - always doing so with a commitment to the manufacturability of your components at a competitive cost.

And, regardless of which stainless steel alloys your engineers specify, our machining and fabrication services will meet your requirements for quality and corrosion-resistance, to help prevent food-borne contamination in the equipment.

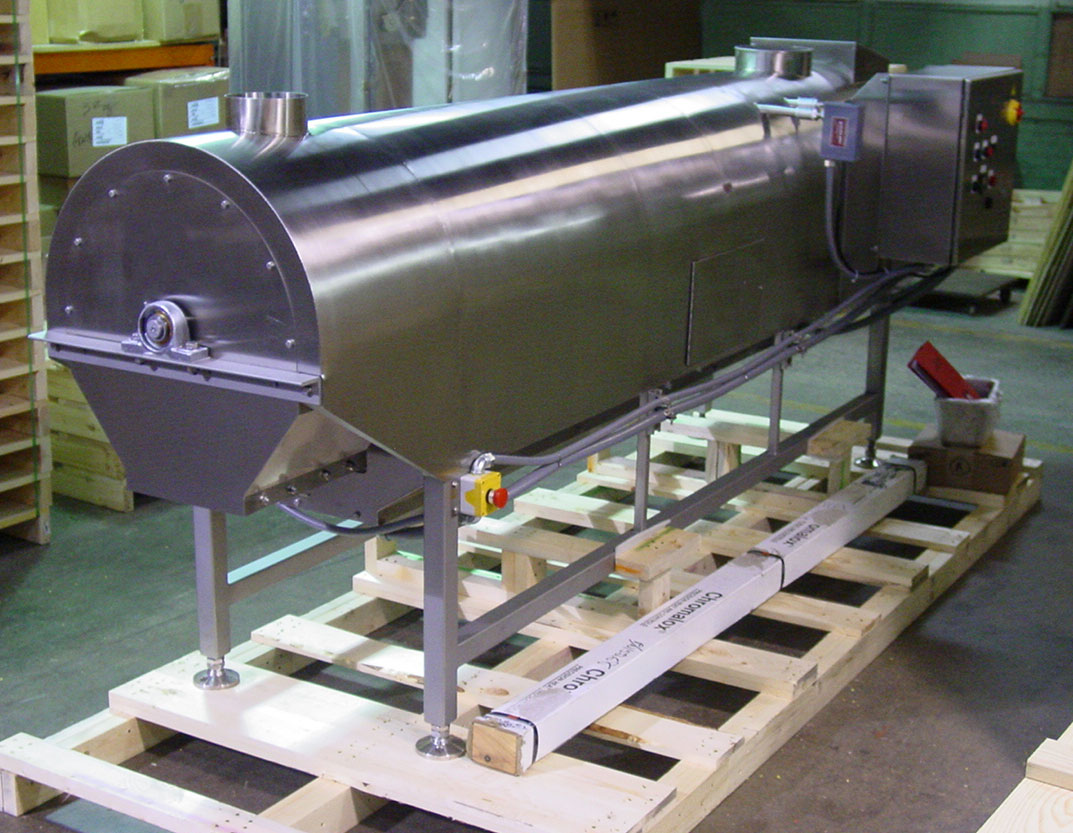

Our experience fabricating stainless steel components to the exacting standards required by food processors includes:

EXAMPLE OF STAINLESS STEEL FINISHES

| 2B | Commercial #4 | 3A Dairy* | Bead Blast | |

|---|---|---|---|---|

| APPLICATIONS | Material handling and processing, direct food contact | Cosmetic #4, for guarding food processing and shrouding | Used in Hygienic clean rooms, 3A Dairy Process and for compliance with 3A Dairy standards | Provides a uniform finish for structural, material handling and food handling applications |

| SANITATION | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Suitable for use in caustic, sanitary wash down procedures | Bead blasting on some stainless steel alloys is suitable for use in caustic, sanitary wash down procedures |

| NOTES | A 2B finish may be preferable - and more economical - for your application depending upon the specific alloys and compliance requirements of your application | Commerical #4 60 RA or better No. 4 finish is NOT compliant with 3A Dairy Sanitation standards |

Including flat surface finish, all welds must be ground and polished to 3A standard, to meet the requirements of the Dairy and Cheese manufacturing industries | Bead blasting does not always produce a 'smooth' finish. The RA, or measure of smoothness, depends entirely upon the stainless base metal used, the blasting media and process. Alloys such as 304 and 316 stainless accommodate this finishing process |

*3A Dairy Sanitation Requirements include stringent attention to fabrication processes that eliminate pits and holes which can harbor bacteria.