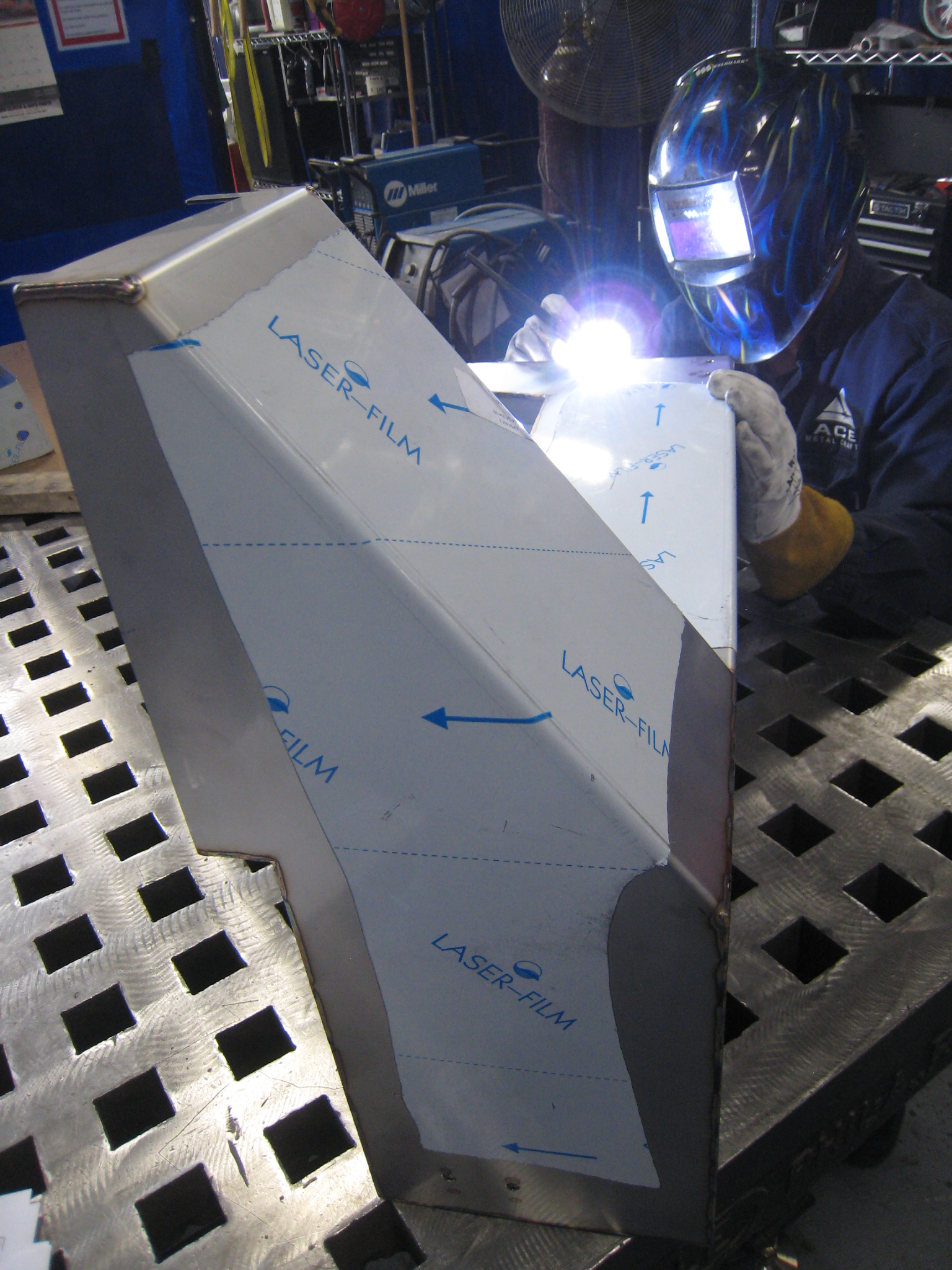

Welding stainless steel requires an experienced knowledge of chemistry, mechanical properties and corrosion resistance to avoid potential trouble.

Working with all types of stainless steel, every day, our welders are able to hold the tightest of tolerances while avoiding challenges often faced by less-experienced welders including oxidation, warping and hot-cracking, which can lead to damaging corrosion as a consequence.

Our welders have a game plan; they’re ready to build anything. OEMs bring their challenging stainless steel welding projects to ACE, because they know our level of skill is unique. As one customer put it,

“The Sanitary welding requirement is where ACE excels.”

WELDING EQUIPMENT:

- 6 - Miller Syncrowave 350LX amp TIG welders

- 6 - Miller Max Star 200 TIG inverter

- 5 - Lincoln Precision TIG 275 amp

- 1 - Miller Max Star 150 portable TIG inverter welder

- 11 - Miller 350P amp MIG pulse machines

- 1 - Miller Acu-pulse MIG 400 amp

- 1 – Fronius Mig welder

- 2 - Pro-weld stud welder

- 2 - Stanco 30 KVA spot welders with Entron controls

- 1 - Acme 50 KVA spot welding machine

- 40 - Weld tables up to 6’ x 18’

AUTOMATED WELDING EQUIPMENT:

- 1 - Orbimat 165 orbital welder ¼” thru 3” outside dimension

- 1 - Weldine Automation seam welder 48” welding length, material thickness up to 7ga.

- 1 - Steel Max straight line MIG welding automation

MATERIAL HANDLING:

- 60’ x 250’ High Bay with (2) 5 ton and (1) 10 ton gantry cranes

- Automated material handling for tanks and cylindrical weldments up to 4000 LBS capacity

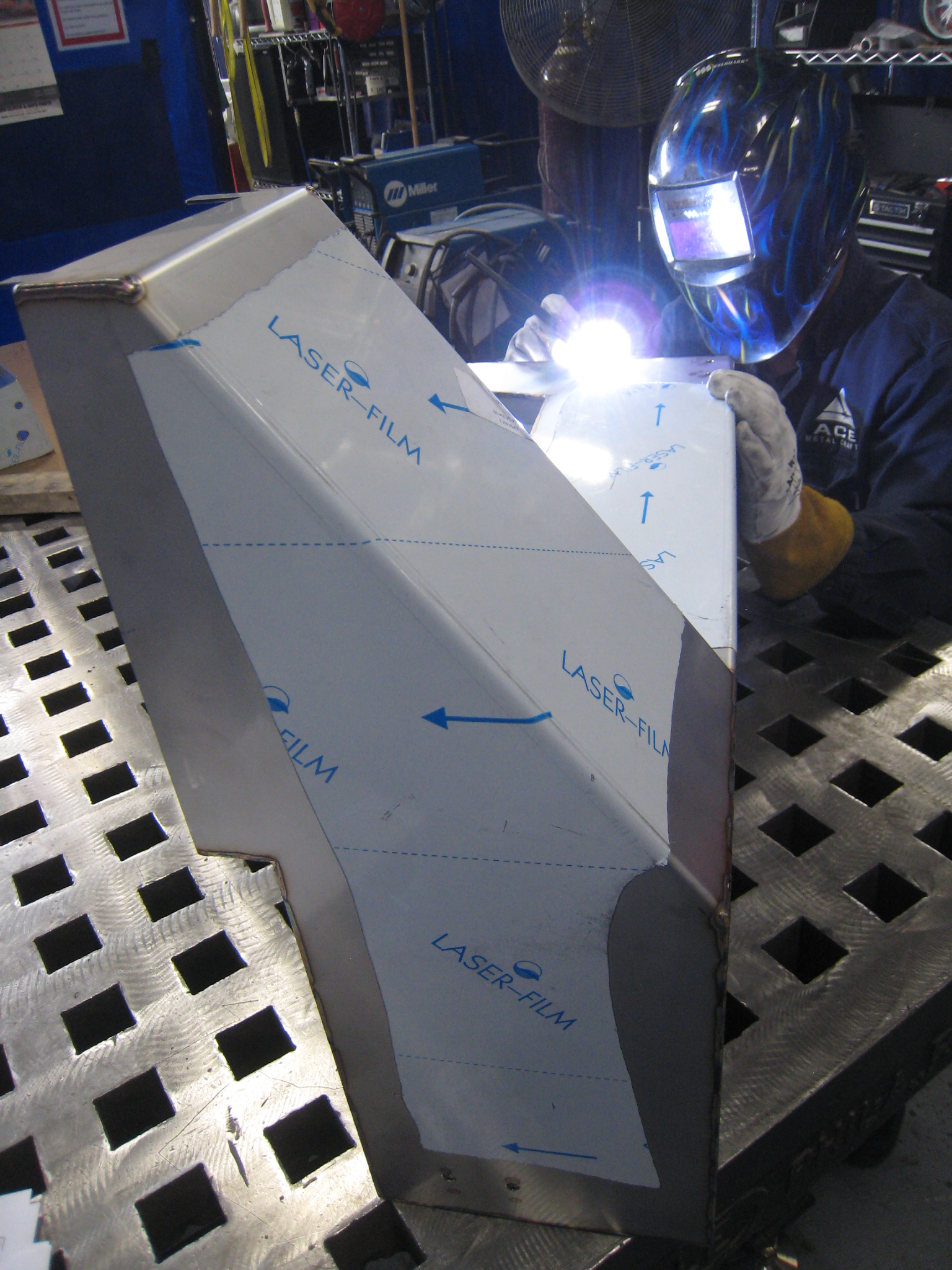

Welding stainless steel requires an experienced knowledge of chemistry, mechanical properties and corrosion resistance to avoid potential trouble.

Working with all types of stainless steel, every day, our welders are able to hold the tightest of tolerances while avoiding challenges often faced by less-experienced welders including oxidation, warping and hot-cracking, which can lead to damaging corrosion as a consequence.

Our welders have a game plan; they’re ready to build anything. OEMs bring their challenging stainless steel welding projects to ACE, because they know our level of skill is unique. As one customer put it,

“The Sanitary welding requirement is where ACE excels.”

WELDING EQUIPMENT:

- 6 - Miller Syncrowave 350LX amp TIG welders

- 6 - Miller Max Star 200 TIG inverter

- 5 - Lincoln Precision TIG 275 amp

- 1 - Miller Max Star 150 portable TIG inverter welder

- 11 - Miller 350P amp MIG pulse machines

- 1 - Miller Acu-pulse MIG 400 amp

- 1 – Fronius Mig welder

- 2 - Pro-weld stud welder

- 2 - Stanco 30 KVA spot welders with Entron controls

- 1 - Acme 50 KVA spot welding machine

- 40 - Weld tables up to 6’ x 18’

AUTOMATED WELDING EQUIPMENT:

- 1 - Orbimat 165 orbital welder ¼” thru 3” outside dimension

- 1 - Weldine Automation seam welder 48” welding length, material thickness up to 7ga.

- 1 - Steel Max straight line MIG welding automation

MATERIAL HANDLING:

- 60’ x 250’ High Bay with (2) 5 ton and (1) 10 ton gantry cranes

- Automated material handling for tanks and cylindrical weldments up to 4000 LBS capacity